We will fulfil the promise of a decarbonised future

The Elestor solutions

A rapid transition to a new and entirely clean energy system is now possible, thanks to Elestor’s large-scale flow battery that can store renewable energy for long periods of time.

Learn moreThe fundamentals

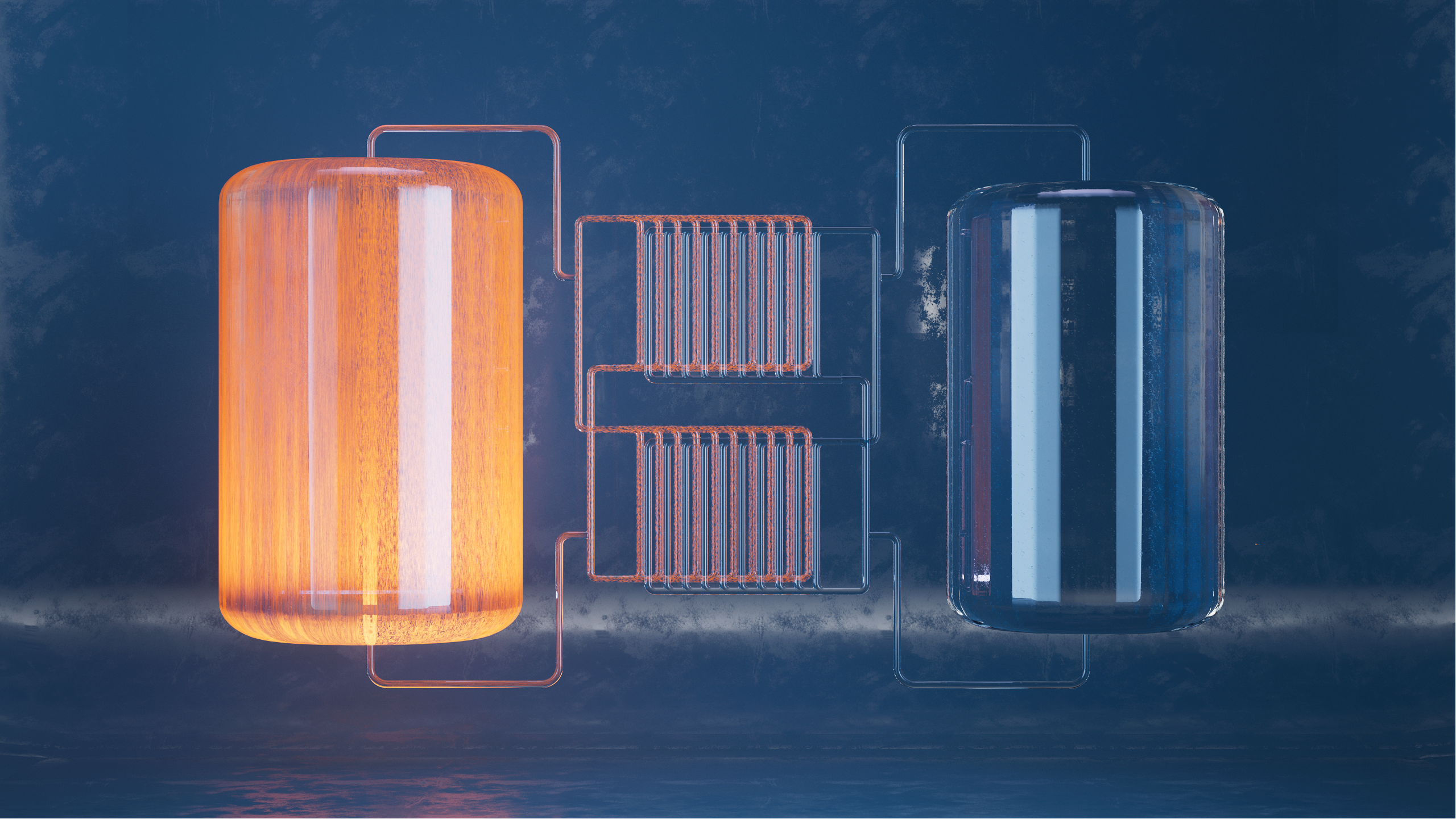

The flow battery consists of an electrolyte and a hydrogen tank, separated by a membrane stack made up of electrochemical cells.

Learn moreWorking principle

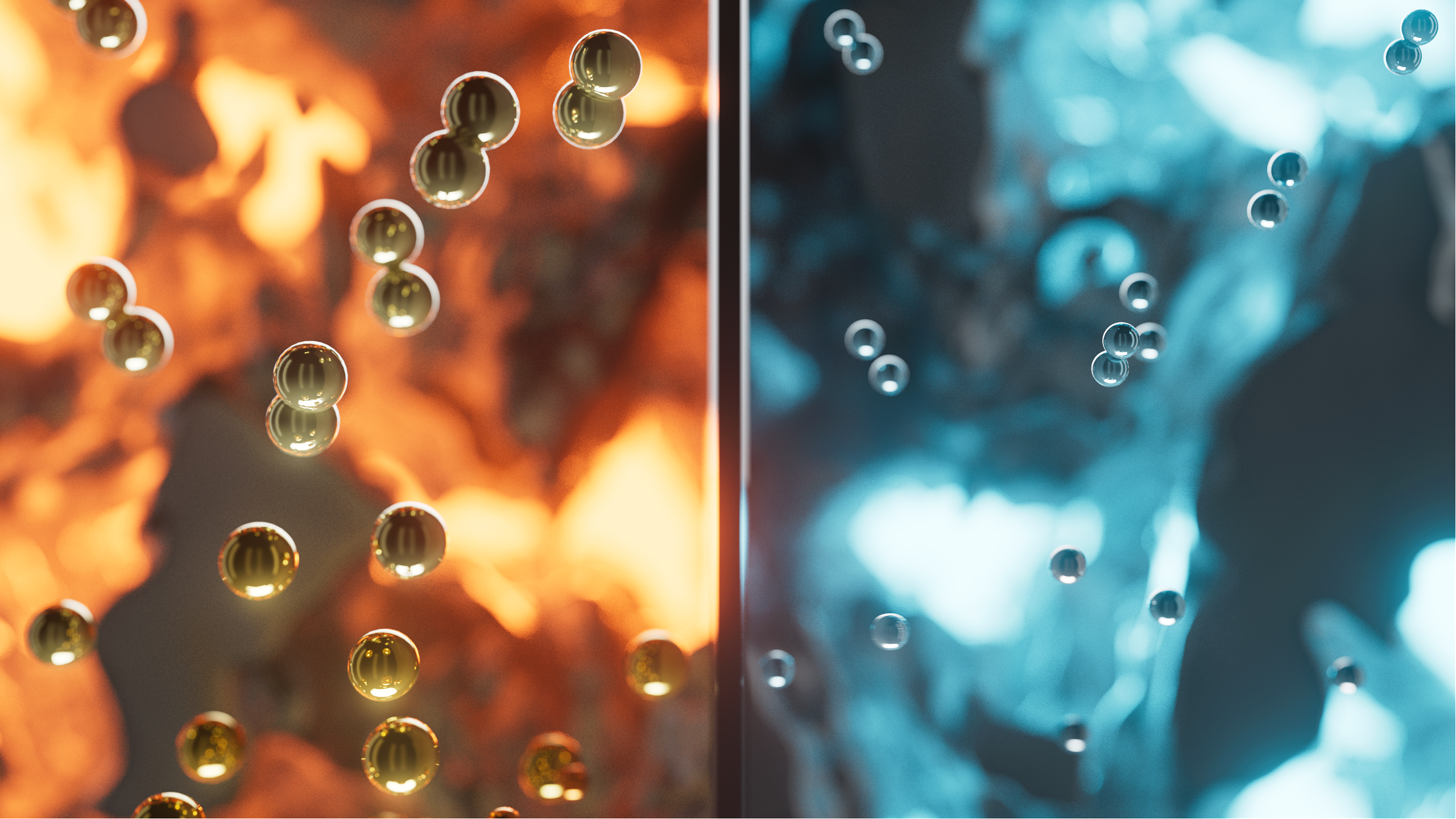

Protons travel through the membrane to absorb or release electrons during charging or discharging.

Learn moreHydrogen & iron

Both materials are readily available and as the flow battery is a closed system they last a long time.

Learn more

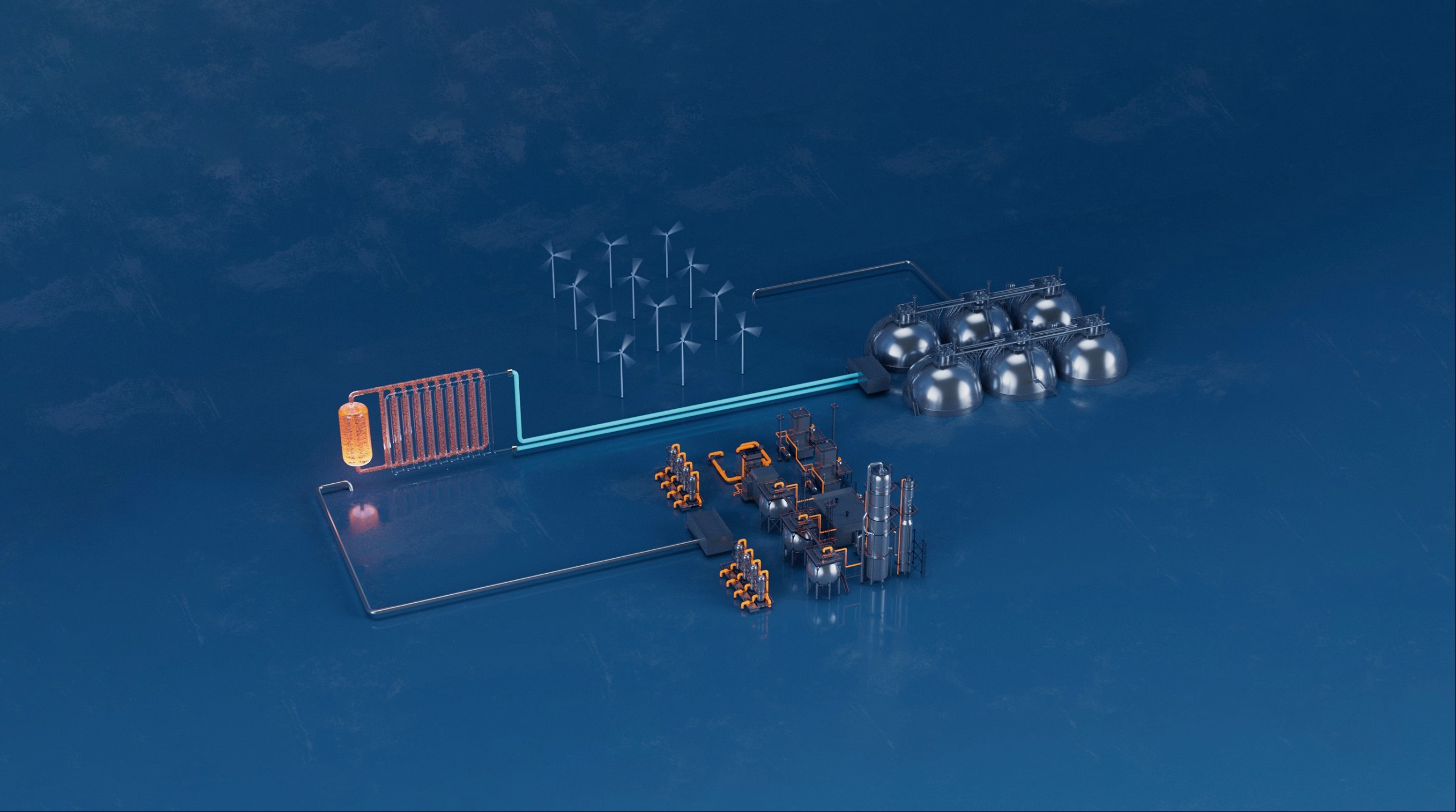

Scalability

Elestor's flow battery is incredibly flexible and easy to scale, not only because hydrogen and bromine are abundant materials all over the world. To increase your power, expressed in megawatt, simply install additional membrane stacks. Similarly, expanding the electrolyte and hydrogen tanks enables you to increase your capacity, expressed in megawatt hours. The battery can even be integrated with existing hydrogen pipelines, removing the need for a hydrogen tank altogether.

Learn more

Life Cycle Analysis

Elestor conducts rigorous LCAs to evaluate and minimize the environmental footprint of their flow battery technology. By considering factors such as resource consumption, emissions, and waste generation, Elestor aims to continuously improve the sustainability of their products and contribute to a cleaner, greener future.

The flow battery family

Purely from a scientific perspective, flow batteries can be built around a large variety of different chemistries, by using different active materials (‘redox couples’). Whether a particular chemistry eventually also reaches commercialization phase, depends on several factors, of which the most important ones are:

Power density

The power density determines the power the flow battery can deliver per m2 of membrane surface area. A low power density translates into the need for many m2 of cell materials, more in particular, of membranes. In such case this becomes a significant cost driver for the total flow battery system.

Learn moreEnergy density

The energy density determines the energy the flow battery can store per m3 of active materials. A low energy density translates into the need for large quantities of active materials, potentially adding up to high costs. Furthermore, a low energy density generally results in systems with large physical dimensions.

Learn moreCost of active materials

When designing flow batteries with a large storage capacity [kWh], the costs for the active materials become dominant in the total system costs.

Learn more

Hydrogen infrastructure

Elestor capitalizes on the anticipated hydrogen infrastructure rollout by integrating their flow battery with hydrogen gas pipes. This eliminates the need for separate hydrogen storage, reducing system footprint, capital expenditure, and storage costs, bridging energy storage worlds.

Learn more