Every new technology, including Elestor’s flow battery, must be permissible. Before it can be adopted widely, this emerging technology must secure a license to operate, both metaphorically, in the sense that it will require the approval of ordinary people, and as an actual permit issued by regulators.

By Joep Lauret, Project and Compliance Manger, Elestor

Long Duration Energy Storage (LDES) systems are generally intended to store very large amounts of energy. The duration must be long, as these systems are expected to provide electricity during relatively long periods when there is neither sufficient sun nor wind to generate enough power. Hence, the best way to describe what Elestor is offering, is Long Duration Large Scale Energy Storage, but let’s stick with LDES for now, as this is the established moniker.

The requirement for large-scale electricity storage is there to store a lot of electricity in cases where demand is great during such periods. As a consequence, electrochemical LDES batteries have to store substantial amounts of chemicals in very large tanks. As such, these batteries bear little resemblance to those found in cars, or even in container-sized systems such as those used by data storage facilities to ensure the power supply to their computers remains uninterrupted, or as a source of mobile power for industries ranging from construction to film sets and festivals.

Electrochemical LDES batteries, such as Elestor’s flow battery, can be huge. As big as supermarkets or sports stadiums in some cases.

This can be challenging.

License to operate

Every new technology must be permissible. Before it can be adopted widely, an emerging technology must secure a license to operate, both metaphorically, in the sense that it will require the approval of ordinary people, and as an actual permit issued by regulators.

A technology’s permissibility therefore depends on its ability to win over hearts and minds, and its ability to prove that it is safe. In the real world, it is essential for any technology company to speed up this permissibility process, and permissibility does exactly that. The more permissible a technology, the quicker it will be to secure its license to operate.

This was one of the most important reasons why Elestor decided to officially transition from hydrogen-bromine to a hydrogen-iron chemistry.

This paper will offer cursory explorations of some of the subjective aspects that we believe affect our hydrogen-iron flow battery’s permissibility, but its main focus will deal with compliance challenges and solutions.

Size matters

It is a law of nature that storing large volumes of potentially hazardous chemicals will amplify both the energy potential and the degree of hazard. This can make it difficult to secure permits for large flow batteries.

This is especially the case when quantities of hazardous chemicals supersede certain thresholds. The Seveso directive is pertinent in this regard, as it defines where the thresholds should lie in order to reduce the risk of accidents and to minimise their impact on human and environmental health in the event that they occur. With our hydrogen-iron (H2-Fe) redox flow battery, Elestor has introduced an optimal LDES solution that is superior to our earlier battery design, which worked with hydrogen-bromide (HBr) as an active substance. This HBr was bi-directionally converted into bromine species (Br2) and hydrogen (H2). Such an HBr flow battery has outstanding power density (W/cm2) and energy density (Wh/l) as well as a good energy efficiency. However, the substances in such battery are also highly corrosive and even poisonous. Consequently, containment required special and expensive materials, including ‘forever chemicals’. We invested a lot of research and development time to make a switch to a non-toxic chemistry possible, as we wanted to remove the need for expensive forever chemicals and at the same time speed up our commercial journey to market.

Our solution, the hydrogen-iron H2-Fe chemistry, is obviously also a compromise, just as all technology choices are. In this case, the power density and the energy density are somewhat reduced relative to our previous technology, but we believe this is acceptable as it is a stationary system that does not need to be compact, the way batteries used in mobile applications do. Moreover, the energy efficiency will still be very good when compared with most other alternative technologies. Added to this is the hydrogen-iron flow battery’s much lower total system cost, which aligns fully with our declared mission to reduce electricity storage costs to the absolute minimum.

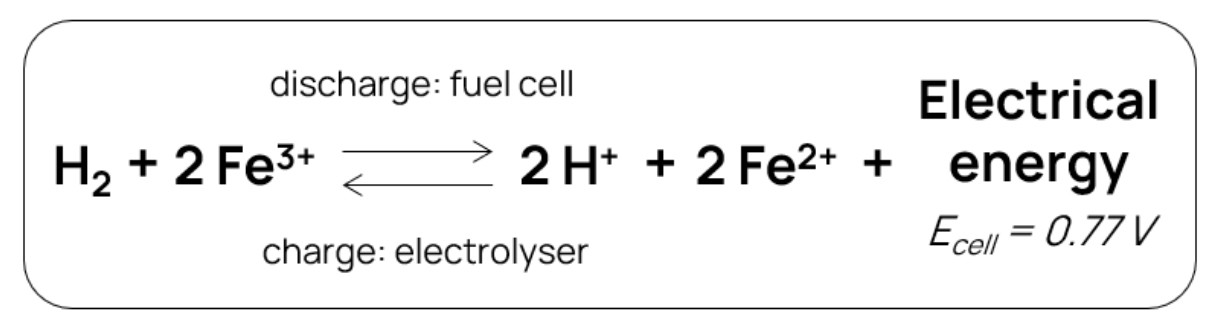

The name of the hydrogen-iron flow battery reveals what its active chemical substances are. These are applied in order to exchange energy and thus to enable the battery to charge and to discharge. H2 stands for the hydrogen molecule that is composed of hydrogen ions (H+) that are being exchanged in this battery. In addition, this battery uses a liquid electrolyte where iron ions (either Fe2+ or Fe3+) are active. These ions originate from Ferrous sulphate (FeSO4) that is dissolved in water (H2O) together with sulfuric acid (H2SO4). Then, during the energy exchange, there are electrons going around (e-) that represent the electrical part in the electrochemistry.

A flow battery that is working with these abundant and cheap chemicals is relatively safe, especially as these substances are not poisonous. This last point is a major advantage for public safety and thus for both permittability and permissibility.

An earlier Elestor flow battery was using hydrogen bromide and bromine as an active species. Although that battery proved to have great technical properties and although Elestor found great ways to mitigate risks and actually make that battery safe, the handling of the bromine element required the use of expensive materials and equipment to contain the substance and to mitigate risk. With the H2-Fe chemistry, these risks have been dramatically reduced and in some cases removed entirely.

But again, as all energy storage comes with a degree of risk, there are still hazards that must be controlled. The first is the containment of the hydrogen and the acidic electrolyte, but this is not particularly challenging as affordable, professional and proven practices will be applied. The industry has a very good track record in this regard. Having minimised the risk of a containment failure, the second challenge is to make sure that the impact of such an unlikely scenario would be very low, in that it would secure public safety. Again, this will be done with proven solutions, hence safety concerns no longer make it difficult to secure a permit to install and operate Elestor’s flow battery.

Hydrogen-iron’s value propositions

Elestor’s hydrogen-iron H2-Fe battery has some good value propositions.

First of all, Elestor flow batteries are intended as land based stationary systems. This makes it less relevant to store hydrogen at high pressures with the objective to reduce the system’s overall volume. In contrast to mobility solutions that often work at 300 or 700 barg or in contrast with typical hydrogen pipelines that might work on 60 barg, the Elestor battery is designed to work on relatively low hydrogen pressures. Low pressures are easier to handle, they are safer and they do not require very expensive equipment materials. Hence, even if a leakage were to occur, the leak rates would be minimal.

Having removed the need to significantly pressurise the hydrogen tank, we have also cut cost. The Elestor batteries are capable of working with a pressure range that varies from near atmospheric pressures towards maximum storage pressures of 16-20 barg. In case of atmospheric pressures. the hydrogen can be stored in ‘double membrane domes’. In case of pressurised hydrogen, the chemical can be stored in larger metal tanks.

Such storage solutions are well known in the industry and have a good track record as well. So, although hydrogen is flammable when mixed with air and then potentially also explosive, the risk with the Elestor battery is exceptionally low, as the hydrogen is retained within a closed loop system without air. And opposed to water electrolysers, which also produce oxygen, there is no risk whatsoever that oxygen enters the hydrogen circuit.

Secondly an Elestor battery uses the liquid electrolyte which is acidic but not poisonous. Neither is it vaporising harmful gasses, even in the unlikely event of an accidental release. Again, we rely on established industry practises for storage and construction. These will be applied in a fashion that is well known for storing a solution of sulphuric acid (H2SO4). In short, therefore, we minimise or eliminate risks, by way of proper engineering in accordance with established industry and regulatory standards, combined with the active prevention of accidental releases, again by applying familiar and proven solutions.

Third, in Elestor’s flow battery, the physical locations of power generation and energy storage are separated. This reduces or removes fire risk, which is usually related to power exchange positions connected to storage tanks *. As we have separated power generation and storage with a separator valve, we can almost instantly shut down the source of fuel (hydrogen) in the unlikely event of a fire at the power generation side. Our fail-safe automated fire extinguishing system is installed as a back-up and to minimise damage. This setup is highly appreciated by authorities that oversee public safety, such as the fire brigade or local and national safety institutes. Consequently, it makes it quicker and easier to secure permits.

A fourth benefit is that very large hydrogen-iron flow batteries can be built without being subjected to the Seveso requirements. The Seveso Directive forms a key part of the EU’s commitment to environmental and public safety. This directive aims to prevent major industrial accidents involving dangerous substances and to limit their consequences for human health and the environment. The Seveso Directive is applied through a combination of strict regulatory measures, reporting requirements, and safety protocols. Facilities are categorised into lower-tier and upper-tier, based on the quantity of the hazardous substances they handle. Each category has specific requirements for safety measures and reporting. Logically, systems that need to comply with Seveso requirements are more difficult to secure permits for. At very large sizes, however, any energy system is likely to enter into an area where the Seveso requirements apply.

With the earlier Elestor flow battery, which was based on hydrogen bromide (HBr), it was expected to enter Seveso territory somewhere between 10 and 20 MWh as quantities of hazardous bromine could be exceeded. With the current Elestor hydrogen-iron H2-Fe flow battery, the substance thresholds for any permittability is dictated by the quantity of hydrogen and not by the quantity of liquid electrolyte. This is because poisonous substances are no longer present in the electrolyte.

For hydrogen the Seveso threshold limits are set at respectively 5 tonnes for the lower threshold and 50 tonnes for the higher threshold . This corresponds with larger hydrogen-iron H2-Fe batteries of ~80 MWh and ~800 MWh respectively. For Lithium batteries, which offer an alternative LDES solution, Seveso thresholds still need to be defined. It can be expected that large scale batteries will be subject to Seveso requirements already with battery sizes around 20MWh . This means that with Elestor’s hydrogen-iron H2-Fe chemistry, it is possible to install much larger battery systems without being subjected to Seveso rules. And that is a clear benefit, as it speeds up approval processes, reduces the administrative burden, and helps curb cost.

In the Netherlands, after consultancy from an expert organization and from verification with safety authorities, it is concluded that:

- There are no big concerns originating from Elestor’s hydrogen-iron electrolyte as there are no poisonous substances involved. Logically, the soil needs to be protected from acidic leaks, but that is something that is typically achieved with double containment systems, which functioning has a good track record.

In this context it is noted that for rules as to be applied, the battery storage tanks are formally not ‘storage tanks’ but they are ‘buffer tanks’ as they are part of the process.

- The quantity of hydrogen gas is the key factor when it comes to public safety requirements and environmental permits. Up to the lower Seveso thresholds limits, there currently is no formal burden to use the quantities of hydrogen typically required in Elestor’s hydrogen-iron flow batteries.

For an actual permit arrangement on any location, it must be proven that public safety is not at stake and that risks are below standard limit values. Public safety is then assessed with standardized Quantitative Risk Assessment (QRA) calculations that are globally used and accepted, although there are minor variants between countries.

To get a permit, authorities might also ask for other dedicated safety studies to be carried out, such as a Hazard and Operability Study (HAZOP), and potentially a Bowtie study or other studies according to industrial best practices, for example to prove mutual safety distances against a fire hazard. The outcomes of all these studies must prove that safety risks are within standard acceptable limits as applicable at the projected battery locations.

As the Elestor battery will comply with the regulations and directives as applicable in the EU that are relevant for the CE-marking, it will not be burdened by such approvals processes. Other continents might simply accept the EU’s judgement, or they might operate with other rules and regulations.

Added to the safety aspects that are relevant to any permit application, local authorities will of course also consider the building construction, which must fit in with the location. Such considerations might relate to local people’s willingness to accept a flow battery as a neighbour, or they might relate to local infrastructure such as roads and other transport links, and the potential to connect to a grid. In our experience, there are often fewer objections to the construction of hydrogen-iron flow batteries.

* Elestor’s flow battery design separates the physical locations of power generation and energy storage, which is significantly reducing the risk of fire propagation. Fires typically originate from power exchange points, not from storage tanks. By separating these functions, an incidental fire in the power exchange unit will not automatically spread to the storage area. A safety separator valve enables the immediate shutdown of hydrogen flow, which is then removing a potential fuel source. And an automated fire extinguishing system ensures that any remaining fire is quickly suppressed, minimising further damage. This complete setup is well regarded by public safety authorities, including fire brigades and regulatory agencies, and therefore supports a faster and smoother permitting process.

————

1/ https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32012L0018#anx_I Look for CAS number 1333-74-0

2/ Roughly calculated with an average energy density of 200 Wh/kg and respectively 50 and 200 tonnes of Lithium (as quantity of dangerous substance), it can be concluded this would scale to 10 MWh and 40 MWh. Although Lithium batteries are not directly referred in the Seveso directive, this is based on the quantity of hazardous substances, and we do see such sizes confirmed in scientific texts such as https://www.researchgate.net/publication/352158070 , page 17 and https://www.researchgate.net/publication/359203817_Hazardous_Substances_potentially_generated_in_loss_of_control_accidents_in_Li-ion_Battery_Energy_Storage_Systems_BESS_storage_capacities_implying_Hazardous_Substances_Consent_obligations

With € 30 million, the SLDBatt project in the context of the Growth Fund Material Independence & Circular Batteries is the largest R&D project into battery technology for long-term storage of sustainably generated electricity in the Netherlands

Minister Hermans with SLDBatt consortium representatives at IEA Energy Storage Symposium in Rotterdam (credits: Mathias de Graag / RVO)

Read more

Elestor’s Hydrogen-Iron Flow Batteries: Powering Europe’s Resilient and Sovereign Energy Future

In its Innovation News Network article from 15 July 2025, Elestor illustrates how its hydrogen‑iron flow batteries can deliver long‑duration, modular energy storage to bolster Europe’s grid stability and strategic autonomy. The story highlights the team’s use of abundant, safe materials and regulatory-aligned design to ensure rapid deployment at scale.

Read more

Permissible technology

Why we find it easy to gain approval for our hydrogen-iron flow battery from both regulators and the general public

Read more